Industrial textile die cutting machine emerges as a game-changing solution, engineered to tackle the most demanding textile cutting tasks with unparalleled accuracy and speed. Whether you’re processing cotton, polyester, non-woven fabrics, leatherette, or thick upholstery materials, this machine redefines productivity standards for textile businesses of all scales.

Designed to handle both thin fabrics (such as garment linings) and heavy-duty materials (including automotive upholstery fabrics and industrial felt), the industrial textile die cutting machine offers adjustable cutting depth and pressure settings. This adaptability ensures perfect results for every application—from intricate patterns for fashion accessories to large-format cuts for home textiles like curtains and carpets. The non-marking cutting table further protects delicate fabrics from scratches, preserving the integrity of your premium materials.

The key features and advantage of industrial textile die cutting machine

- Automatic lubrication system ensures all moving parts receive consistent lubrication, reducing component wear and extending the machine’s service life to over 8 years. Additionally, built-in oil cooling systems regulate hydraulic oil temperature during long working hours, maintaining stable pressure and preventing system failures.

- One feeding table, available to sheet and rolls materials, is easily operated by one worker.

- Cutting stroke setting constructure combined with the cutting knife and cutting height make stroke setting easy.

- Cutting depth can be fine adjusted.

- 3-10 seconds for one stroke, about 2000-3000 pieces of leather can be cut out.

- Central automatic lubrication system, and brand parts ensure the durability and stability.

| Name | Industrial textile die cutting machine |

| Model | DSFCM-120 |

| Maximum cutting force | 120 Tons |

| Distance from upper board to worktable | 50-200 mm |

| Cutting area | 1600×900 mm or 1400*900 mm |

| Main motor power | 11 KW |

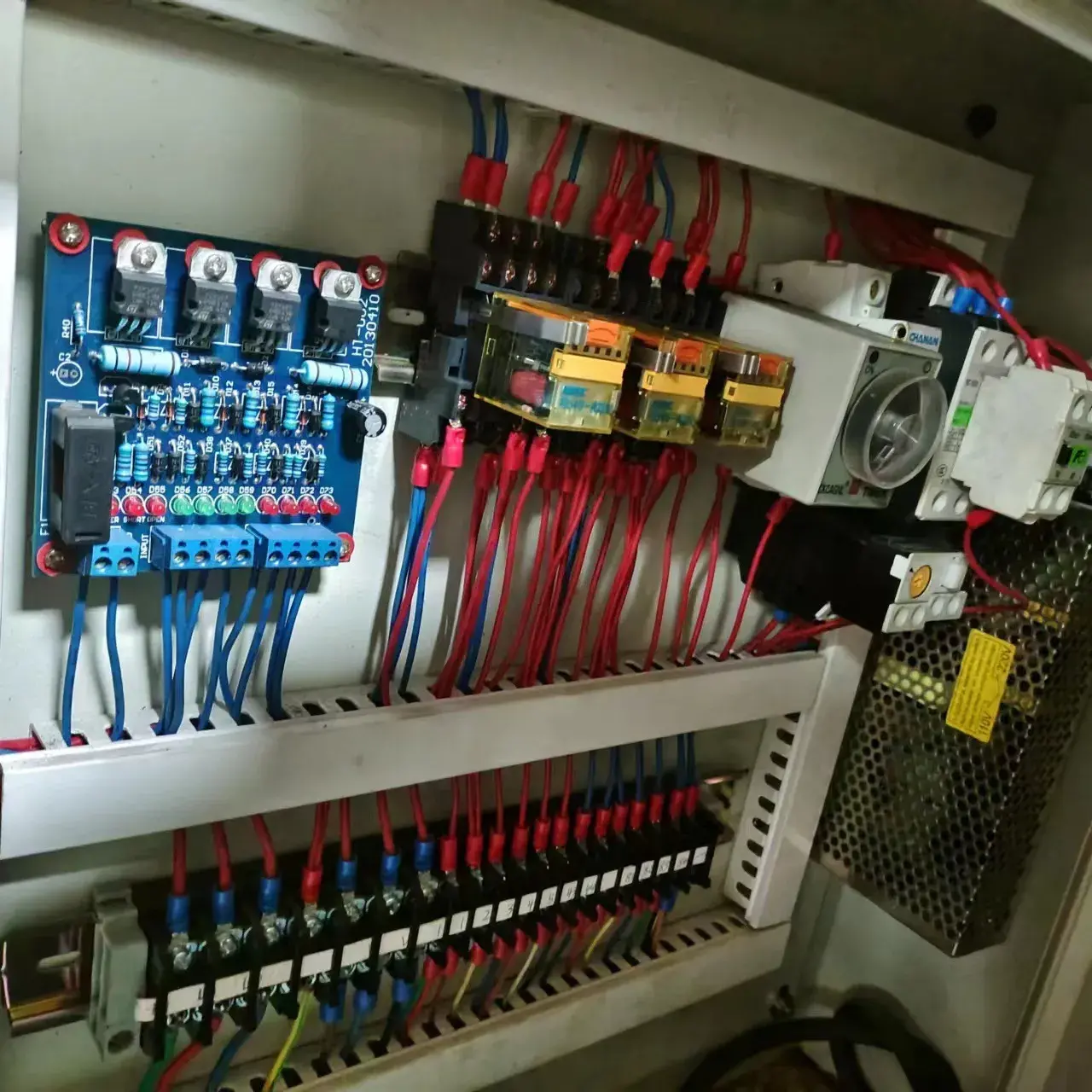

| Electric Supply Voltage | 440/415/400/380/220/200 V |

| Machine weight (approximate) | 4200 Kg |

| Application | leather processing, garment, shoe making, bag making, packaging, toys, stationery, auto inner decoration and emulation flower industry |

Why choose our industrial textile die cutting machine?

Its low-maintenance design reduces downtime and operational costs—key benefits for busy production facilities. Industrial textile die cutting machine also incorporates safety features like emergency stop buttons, protective enclosures, and sensor-based collision avoidance, ensuring a secure working environment for your operators. Upgrade your textile production line with our industrial textile die cutting machine—where precision, speed, and durability converge to drive your business growth. Contact us today to learn more about our machine specifications and tailored solutions for your industry needs!