Our sponge die cutting machine is a specialized industrial equipment designed for precision cutting of sponge, foam, and other flexible materials. It integrates mechanical engineering, automatic control, and intelligent operation, solving the pain points of low efficiency, poor precision, and high material waste in traditional manual or semi-automatic sponge processing. Widely used in furniture manufacturing, automotive industry, packaging industry, and daily necessities production, and cleaing sponge die cutting equipment has become an indispensable core device for upgrading the sponge processing industry with its advantages of high efficiency, precision, and versatility.

The core features and advantage of sponge die cutting machine

- Dual-slide Table Design: Equipped with two interchangeable sliding tables (working table and feeding table) that operate alternately. While one table is processing materials, the other can be loaded with new sheets, eliminating downtime and achieving non-stop production.

- Automatic Feeding & Positioning: Integrated with a precision feeding system that automatically aligns materials with ±0.1mm positioning accuracy, reducing human error and ensuring uniform cutting results.

- Intelligent Control System: Adopts PLC with a touchscreen interface, supporting parameter setting (cutting pressure, speed, stroke), program storage (up to 100+ groups), and real-time production monitoring (output count, error alerts).

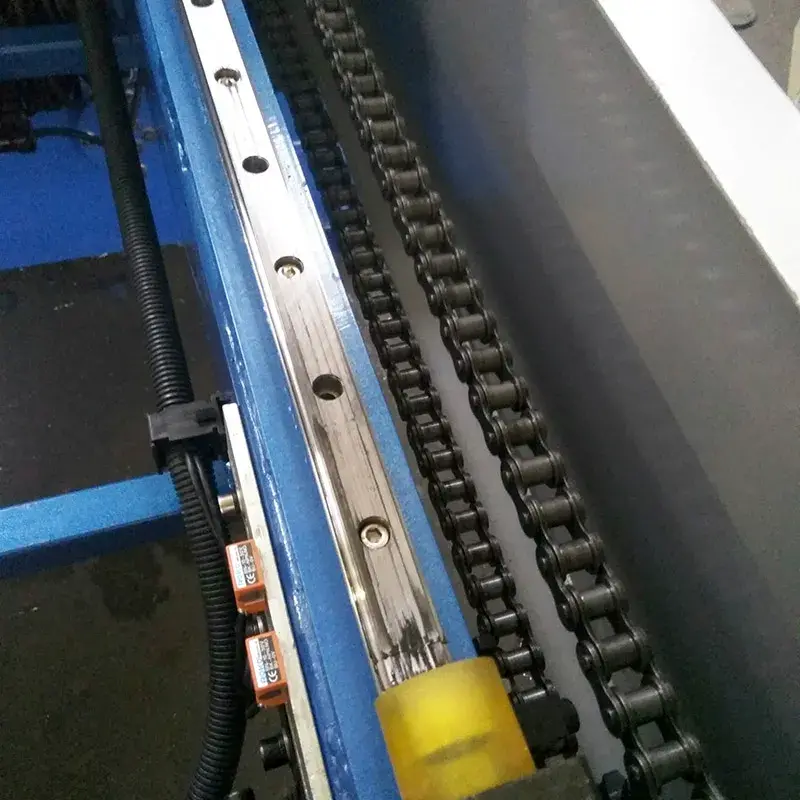

- High Cutting Accuracy: Features a rigid frame structure and precision linear guides for the sliding table, ensuring stable operation and cutting accuracy of ±0.05mm.

- Durable Life: Key components (slide table, hydraulic cylinder, cutting plate) are made of high-quality steel, ensuring long service life and low maintenance costs.

The significant advantages of sponge die cutting machine

Compared with manual cutting and traditional semi-automatic equipment, the sponge die cutting machine has obvious advantages:

- Efficiency: 4-6 times higher than manual operation, supporting continuous 24-hour work;

- Precision: Cutting accuracy up to ±0.1mm, ensuring consistent product specifications;

- Material Saving: Intelligent nesting design reduces material waste by 15-20%;

- Versatility: Compatible with various sponge materials (polyurethane, EVA, latex, etc.) and multiple cutting shapes;

- Cost Reduction: Reducing labor costs and rework rates, with a quick return on investment.

In a word, our sponge die cutting machine is a key equipment that promotes the automation and intelligence of the sponge processing industry. With continuous technological upgrades, it will further expand its application scope and bring more value to enterprises in improving production efficiency and product quality.